The Screws : technical datas

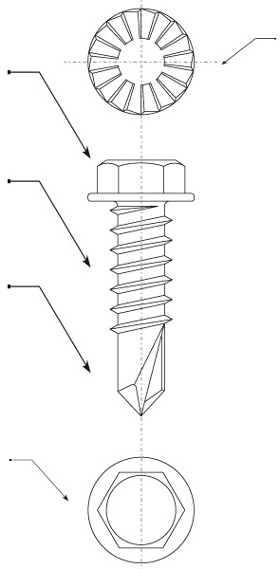

The Self-drilling screw

Head Type

This characteristic is linked to choosing the adequate self-drilling screw. In the DEGOMETAL product line, there are three groups of head types: Pan, Hexagonal or Countersunk head.

The penetration speed of the screw into the drilled support surface depends on the pitch of the thread. The threading of DEGOMETAL selfdrilling screws depends on the dimensions established in compliance with DIN 7504 standards.

Drill bitThe longer it is, the thicker the support surface can be. It can also have two wings which are important for steel-wood screwing. Created through forming, it enables the drilling of the support surface before screwing. On the steel self-drilling screw, the cementation performed after forming enables it to drill steel, aluminium and stainless steel.

However, since this treatment is not possible on stainless steel, the A2 stainless steel self-drilling screw can only drill aluminium.

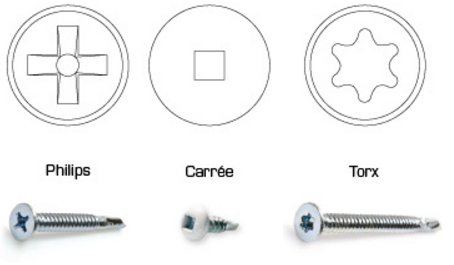

Print TypeSDepending on his choice, the operator can save 40% of the screwing time.

Knurled head (option)

Only for steel self-drilling screws, it slows down the unscrewing even after prolonged vibration. Knurls on TFA & TFA ET screws are tronconic (consisting of 4 lobs): this makes chamfering wood possible during the screwing stage.

On the A2 stainless-steel self-drilling screw, knurls are not advisable, because they scratch the paint of the aluminium support surface during the screwing stage. Aesthetics is of paramount importance when it comes to aluminium joinery.

Materials available

White Zinc-Plated Steel

Stainless Steel A2

Bi-metal (Stainless Steel with Steel drill bit)

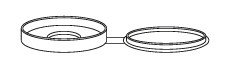

Colours availableEpoxy Paint upon request.

It is possible to place a coloured

plastic cap before screwing

(only for TCB and TCQ screws of ø3.9 and ø4.2 mm)).

Available sizes

| Diameter | from 3,5 à 6,3 mm |

|---|---|

| Lenghts | from 9,5 à 200 mm |

| Materials available | Steel,Stainless Steel,Bimetal |

| head shapes | Pan,Haxagonal,Countersunk |

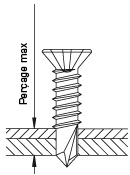

Installation description

Screwing without pre-drilling: the self-drilling screw drills and screws support surfaces all at once.

Les différentes formes de tête

|

Pan head

Usually used on thin metal sheets. |

|

Hexagonal

Wide, often used with a Neoprene washer. |

|

Countersunk

Exact fitting of the head in the support surface for a perfect finish.. |

Print types

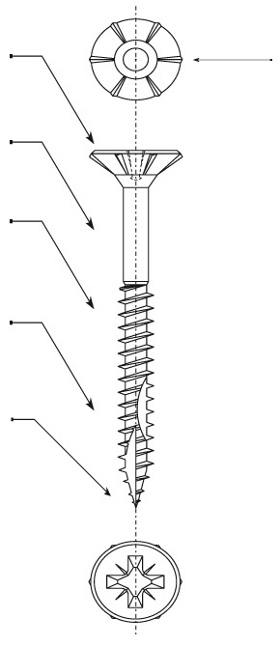

The Woodfast screw

DEGOMETAL also offers a High-Performance Chipboard Screw: WOODFAST.

It is particularly recommended when screwing is diffi cult or under certain constraints like a highly crumbly wood (large-particle chipboard) or hard exotic woods.

With the WOODFAST Screw, screwing into cutting edges and rims becomes possible and easy.

WOODFAST can also be used in the industrial fi eld with automatic feeder bowl systems.

The WOODFAST screw is recommended for difficult assembly.

Torsional Strength

| THREADING | MINIMAL TORSIONAL TRENGTH |

|---|---|

| ST 3,5 | 2,8 |

| ST 4,2 | 4,7 |

| ST 4,8 | 6,9 |

| ST 5,5 | 10,4 |

| ST 6,3 | 16,9 |

Mechanical characteristics

Drilling capacity

Drilling capacity

The tip of the self-drilling screw has to be shaped so as to drill a steel plate, which is needed for the shaping of the internal thread, under conditions specifi ed in ISO 10666:1999 (F) standards.

Internal thread or threading capacity

The self-drilling screws must be able to tap the drilled bore, in accordance with previous point, without having their own threading distorted, when screwed into a test plate, in compliance with ISO 10666:1999 (F) standards.

The Woodfast screw

DEGOMETAL also offers a High-Performance Chipboard Screw: WOODFAST.

It is particularly recommended when screwing is diffi cult or under certain constraints like a highly crumbly wood (large-particle chipboard) or hard exotic woods.

With the WOODFAST Screw, screwing into cutting edges and rims becomes possible and easy.

WOODFAST can also be used in the industrial fi eld with automatic feeder bowl systems.

The WOODFAST screw is recommended for difficult assembly.

Double countersunk head to avoid under-head breaks during screwing into hard wood.

Non-threaded top part to increase contact between the two screwed parts (Only on partial-treading WOODFAST screw).

Lubricated thread to improve penetration into the wood during screwing.

Two sharp notches: One cuts through the wood to avoid splitting. The other picks up wood shavings to avoid potential swelling of the wood.

Sharp end for precise and fast screwing start.

Knurled countersunk head for an exact fi tting of the head in the wood.

Application fields and examples

- Mechanical engineering to soundproof the engine compartment

- Fastening profi les (decorative)

- Waterproofing cabins

- Manufacturing of boilers and bottom-part fasteners

- Covering with thin metal sheets

- Plating to protect insulating layers

- Fastening of cover sheets for refrigerators, freezers, washing machines and dish washers.

- Partition and insulation panels

- Ventilation channels