Advantages of this product :

- Robust threading on parts with low thickness or resistance

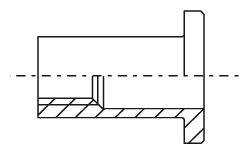

- Blind setting (access only available on one side) in profiles, tubes or caissons

- Will withstand high tightening torque

- Will withstand frequent unscrewing

- A short assembly process